Following my move from the San Francisco Bay Area to Portland, the pace of development on the UFB slowed considerably [due to marriage; kids; crazy external events; lack of money, etc.], with sporadic surges; it could best characterized by the phrase the biologist Stephen Jay Gould used to describe evolutionary progress: “punctuated equilibrium” — denoting long periods of stasis, interrupted by occasional bursts of incremental evolutionary development.

A perfect example of this is the history of the UFB’s brakes.

In the beginning…

Back in the previous century (literally) when I first spec’d the brakes for my “SuperBrompton Project” [based on a re-imagined Brompton, featuring a custom-designed rear triangle and wheels for full-range derailleur gearing; better rider positioning; pro-level high-performance components, bearings, etc., a substantial weight reduction; and improved braking], I thought Magura’s hydraulic “Hydrostop” rim brake seemed like a good choice for a lightweight, compact, powerful brake (and whose hydraulic lines were impervious to the tortuous & torturous tight bends and repeated flexing imposed by the operational exigencies of a compact folding bicycle!).

Accordingly, I included a pair of Magura’s proprietary braze-on mounts on the first custom rear triangle I designed, and the modified Brompton fork on the very first prototype [and the first couple of bikes I sold of this early design].

Continue reading below the images.

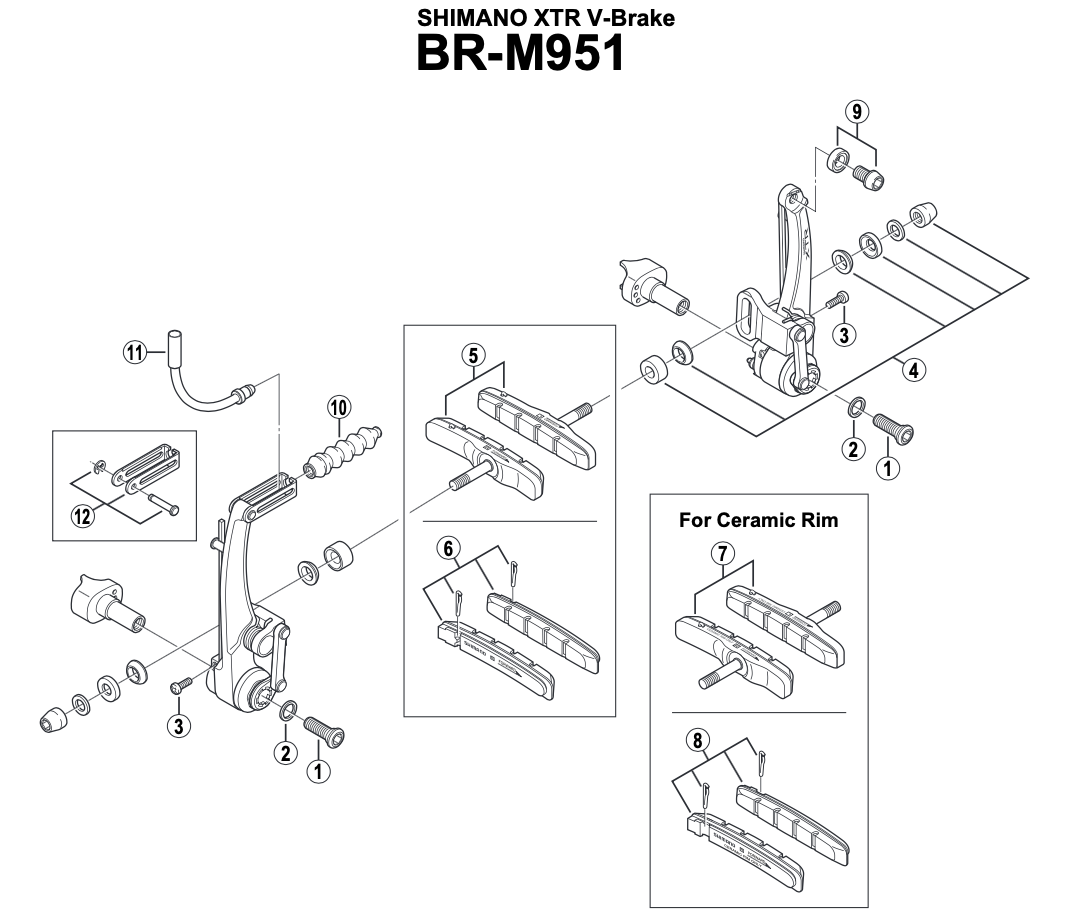

And then in 1996, Shimano introduced their new XTR V-brake [BR-M950; subsequently updated to the BR-M951 in 1999]

Continue reading below the image.

The prospect of a lightweight, compact, powerful, truly progressive cable brake — that mounted on conventional cantilever-style braze-on posts; would never leak and periodically need to be bled and topped-off (as in the case of the Hydrostop); and would be dead-simple for an end-user to adjust, maintain, and service on the road seemed like a better choice, and thus I adopted the XTR as the standard OEM brake for all of the USBs built and sold over the next couple of decades.

Continue reading below the images.

With Shimano’s patented exclusive “Parallel Push®” design – a function of some clever mechanical linkages which enabled the pads to remain parallel to the rim throughout their travel (rather than describing an arc in their path of movement, as in all previous cantilever designs), we finally had a unique and welcome solution to the problem of rapid and uneven pad wear, and degraded performance [as well as the wide-tires-on-narrow-rims clearance issue] that have always plagued small-wheeled folders — and when combined with the clever and powerful progressive action of the XTR levers (a design feature enabled by removing the little plastic blocks inside the levers, thus allowing the cable pivot to move during braking, thereby automatically shifting between two cable ratios on the fly – from an initial high-travel/low-leverage mode to a subsequent low-travel/high-leverage one), the XTR V-brakes were more robust and versatile than other cantilever designs — and immensely preferable to the heavy, flimsy, and very-low-mechanical-advantage long-reach side-pull brakes historically supplied on most folding bikes [which are otherwise encountered only on some older juvenile bikes, and very cheap department store bikes]. So the question of decent brakes on the UFB was nicely resolved…

Continue reading below the image.

…and then one day Shimano decided to kill off my brake!

As the saying goes, the only constant is change — and in retrospect, I suppose I should have seen it coming, but I was really caught by surprise – and pretty upset – when Shimano abruptly announced that they were going to be discontinuing their sleek little engineering marvel – their flagship XTR V-brake [which was so well-suited to the UFB that, upon its introduction, I had literally re-designed the bike around it, and naively assumed I would never have to revisit that design choice] — and that it’s replacement would be…a big, heavy freakin’ disc brake system!

“What about disc brakes – aren’t they supposed to be far superior to rim brakes?”

Yeah…about that — here’s the thing: while historically, there was a legitimate argument for the initial adaptation of motorcycle-style disc brakes to professional all-terrain competition bicycles (bikes that needed to have powerful, robust, and durable brakes for a life barreling down steep, rutted and rock-strewn, muddy hillsides (and that needed to consistently perform under conditions that can quickly hamper – or even sideline – a bike equipped with rim brakes — on rims that are wet, filthy, and/or injured/out-of-true), the bike industry’s wholesale migration to disc brakes — casting aside time-proven lighter, simpler, cheaper and easier-to-service rim brakes — is yet another example of the capricious and stupid marketing-hype-driven/fashion-driven arbitrary decisions commonly determining bicycle industry trends and “standards”.

Moreover, designing a compact folding bike is an exercise which should aim to trim as much excess bulk and weight as possible, in service of the goal of producing a practical, convenient (comfortably carry-able and stow-able) bike optimized for real-world multimodal commuting. Trying to design around the dimensions and structural requirements of disc brake systems results in unavoidable serious compromises…

Continue reading below the image.

Disc brake systems not only place substantial obvious constraints on achievable reductions in weight, and the bike’s folded width, they also exert additional, less–obvious “collateral” limits to both — due to the weight and width penalties imposed by the need to sufficiently “beef-up” frames and forks to provide the added local structural strength and rigidity disc brakes require. Finally, designing around disc brake systems [and their increased torsional loads] comes with a profound reduction in lightweight options for hub selection and wheel design.

So the the decision to specify disc brakes on any design for a “compact folding bike” creates formable obstacles to achieving acceptable folded size and weight – and so constitutes a move in the opposite direction along the path a designer should naturally be heading! What to do?…

With Shimano’s big shift to disc brakes — and in particular, the discontinuance of their unique progressive “Parallel Push” XTR V-brake design, V-brakes suddenly became a considerably less-attractive option for the UFB. But where did that leave me, moving forward?

Continue reading below the image.

Enter the eeBrake…

Soon after Cane Creek debuted the updated, “G4” version [tweaked slightly over the G3 to accommodate the wider rim profiles that the industry has sensibly finally embraced again!] of their ultra-lightweight, beautifully-engineered eeBrake, a few enterprising Brompton accessory makers introduced drop-bolts and-cable-adapter kits designed to enable installing them on Bromptons. I was determined to explore their suitability for the UFB. So I contacted Cane Creek, and was able to order a set for evaluation [even with at OEM pricing, they were frightfully expensive, but I was in need of a reasonable-preforming-yet-truly-lightweight brake solution, befitting the featherweight USB!].

Unfortunately, while the drop-bolts addressed the reach issue, the brake – developed, after all, for road bikes – didn’t provide anywhere near enough clearance for my preferred tire (the very-large-profile Greenspeed Scorcher*).

Continue reading below the images.

I immediately considered developing a replacement longer caliper arm for the brake — to be able to extend the reach to simultaneously do away with the clunky drop bolts AND create enough clearance for the Scorchers.

Wow — Ti Parts Workshop to the rescue!…

Several months passed, when I saw that TPW had developed just such “reach extenders” (replacement caliper arms) as I had envisioned for the eeBrake — to say I was “excited” is an understatement!

Continue reading below the image.

When I received them, I very carefully disassembled the brakes, installed the new caliper arms — and, with some careful fine-tuning — found that they did indeed – just barely – provide enough clearance for my relatively huge (40mm) Scorchers.

Continue reading below the images.

In conclusion…

All things considered, then — apart from the very high cost — I believe the eeBrake, in combination with the extended reach provided by the longer caliper arms — is a nice option for an ultra-light, robust side-pull brake for the UFB (and Brompton owners – with a bunch of cash – looking to lighten up their “bespoke” Brompton!**).

*Note: With the passing of Greenspeed’s Ian Sims – and the subsequent sale of Greenspeed’s brand and existing assets – production of the Scorchers ceased, and those of us who have come to rely on their unique size and many practical advantages were quite concerned about the ominous implications. While some remaining inventory of original Scorcher tires has surfaced here and there, fortunately, a “new” line of tires – closely based on the Scorchers – is now available from the Australian company who acquired the Greenspeed brand, and their domestic inventory. They are branded “TruBlu”, and appear to even be somewhat lighter than the originals [the entire line of Scorchers — including the “60″; “120″; and “HD”/”puncture-resistant”, it should be noted, offered several great benefits — low rolling resistance, great cornering, fabulous comfort, and stability on a wider range of surfaces — but being both quite wide and unfortunately non-folding (i.e. utilizing old-fashioned steel beads, rather than lighter Kevlar or Aramid ones) low weight was definitely not one of those]!

**Note: Historically, there really hasn’t ever been enough clearance on a stock Brompton frame for the Scorcher tires, due to the placement of the rear brake bridge, and the front fork geometry — even without mudguards — so, at the time of this writing, the widest (ETRTO 349-diameter) tires available for a (stock/unmodified) Brompton are the (37mm) Primo Comet, and (35mm) Continental Contact Urban.

Update (Thursday,May 5, 2022):

I recently had the occasion to spend some time riding one of my original SuperBromptons (a hybrid steel/titanium frame 14-speed Rohloff-based conversion that one of my sons is normally riding)…and I am sorry, but boy do I miss those XTR V-brakes — no comparison, as far as I’m concerned, to even the fancy/pricey eeBrakes…damn!

New conclusion…

So when I weigh the hassle and expense of buying; custom-modifying (complex, non-standard mitering is reared for optimal placement on a Brompton or UFB!); precisely fixturing; & welding the titanium V-brake “braze-ons” (on a Ti frame, they’re TIG welded rather than brazed, obviously) to the front fork and rear triangle against the hassle and expense of tediously accurately bending, and mitering, and drilling [at that absolutely critical, extreme and bizarre angle!] those (very-thin-wall titanium!) proprietary Brompton-style crazy-tight-radius rear brake bridges; precisely fixturing, back-purging, and welding the (again, super-thin-wall) ridiculous rear bridges to the rear triangles; unnecessarily subjecting both cable housing runs to tortuous/torturous paths — necessary to arrive at the “wrong-side” cable entry* on the eeBrakes (*vs. the previous easy-peasy opposite-side entry on the XTR V-brakes)…I REALLY MISS THOSE BRAKES!

~ end ~

Leonard,

What a great read! I always knew you were special.

What is the price of your current Ultimate?

Can you just fit a standard but high quality V brake in the conventional ‘in-front of the fork’ position, and make up shorter pads by making a hybrid of roadcaliper slipin-pad holder and Vpad holder bolts so that the fancy parallelogram is not needed?